Bench Top Hydraulic Press: A Manufacturer’s Comprehensive Guide

A bench top hydraulic press offers many advantages in the manufacturing process due to its compact design, versatility, and customizability. Compared to other types of hydraulic presses, bench top presses are smaller and ideal for more precise, lower-volume tasks, like pressing, bending, punching, crimping, stamping, and small assembly work.

Depending on your application, you may be deliberating whether a hydraulic bench top press is right for you.

In this guide, we’ll explain what a bench top hydraulic press is, explore its most common applications, and highlight the key factors you should consider when selecting the right press for your needs.

What Is a Bench top Hydraulic Press and What Is It Used For?

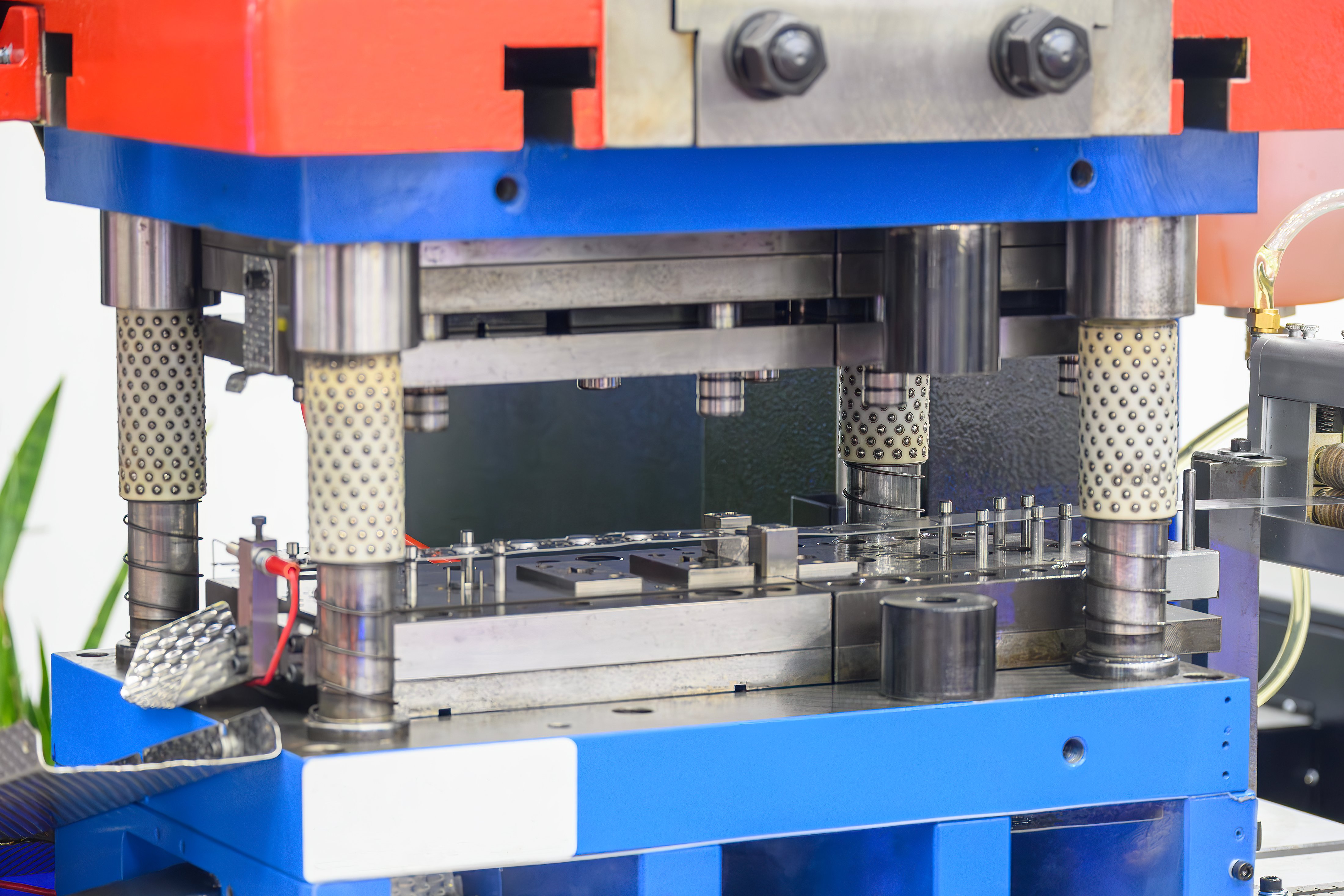

A hydraulic bench top press is an essential tool in industrial, automotive, and manufacturing applications. It’s a powerful machine that utilizes hydraulic pressure to generate a compressive force. It’s often used when there is an insufficient amount of force from manual or mechanical tools.

A hydraulic bench top press easily generates tons of force with high precision and repeatability. This is especially helpful when a high volume of production is required. The bench top hydraulic press is very compact and versatile, making it both portable and applicable for a wide variety of applications.

What Are the Key Features of a Bench Top Hydraulic Press?

The hydraulic bench press has several key features that set it apart from other types of presses. Below, we'll take a closer look at each of these components:

- Power source: The bench top hydraulic press uses an electric motor, which converts electrical energy into mechanical energy. The hydraulic pump converts the mechanical energy into hydraulic power. Although mechanical presses typically operate at higher speeds, hydraulic presses offer greater versatility thanks to their fluid-based power system.

- Versatility of applications: The bench top hydraulic press is suitable for a wide range of manufacturing tasks, including metalworking, assembly, stamping, and electronics. One hydraulic press can be used for different operations. This prevents purchasing multiple machines for individual tasks. Plus, it removes the need to switch between machines as different tasks arise during a project.

- Customizability: Many models of the bench top hydraulic press offer customization for accommodating project needs. This includes different open heights, throat depth, bed size, guarding, light curtains, and tooling, as well as robot and automation integration.

- Durability: Made from tough, high-quality steel, the hydraulic bench top press is built to withstand numerous cycles over the lifespan of the machine.

- Compact design: A compact hydraulic press offers a space-saving design. They are made to fit on a workbench or bench top, perfect for workspaces with limited room.

What Are the Advantages of a Bench Top Hydraulic Press?

The bench top press’ key components can shed light on some of its main benefits, but there are many more advantages beyond these.

The main advantages of hydraulic bench top presses include:

- They’re smooth and precise: Hydraulic power offers finely controlled pressure and speed, making hydraulic bench top presses a great choice for delicate and complex operations.

- They’re user-friendly: Operators love how easy they are to learn to operate and use. The simple controls make them easy to adjust to fit your task.

- They’re portable: These portable presses are ideal for setting up in various locations.

- They’re cost-effective: They’re cost-effective because their simplicity makes them low-maintenance and longer-lasting. Plus, a bench top hydraulic press performs the tasks of many types of machines, so there isn’t a need to buy multiple presses.

What Are Common Applications for The Hydraulic Bench Top Press?

The versatility of a hydraulic bench top press makes it suitable for several different applications, like metalworking and stamping. Here are some examples of ways a hydraulic press is used in industrial applications:

- Metalworking: A small hydraulic press is ideal for bending, forming, and shaping metal parts because of its precision.

- Assembly: Compact hydraulic presses offer significant force, making them great on the assembly line for cars, electronics, and aerospace.

- Stamping: There are three primary stamping operations that bench top presses can help achieve. These include blanking (cutting metal sheets for automotive panels), punching (making a screen), and bending (creating brackets).

- Electronics: The hydraulic press manufactures electronic components and devices with intricate designs. The control offered by the bench top hydraulic press ensures the sensitive material used in electronics isn’t damaged.

Which Industries Use Benchtop Hydraulic Presses?

Hydraulic presses provide the power, accuracy, and control required by a number of industries, including:

- Manufacturing and Fabrication Shops: Hydraulic bench top presses offer precise force for light metal forming, bending, and punching. The compact size of the press makes it ideal for small to medium-sized productions.

- Electronics and Electrical: The hydraulic bench top press is ideal for crimping connectors and terminals, pressing small components, and assembling small electrical devices

- Medical and Laboratory Settings: Hydraulic bench top presses are used for precision forming, device assembly, and material testing. The precise, controlled force enables safe handling of sensitive components.

- Automotive: Hydraulic bench top presses are used in vehicle manufacturing for improving safety, efficiency, and performance. They’re ideal for building many automotive parts, ranging from engine components to advanced driver-assistance systems.

- Aerospace: The hydraulic bench top press is key in aircraft and spacecraft component manufacturing, where durability, weight reduction, and precision are critical. This includes components for navigation systems, structural parts, and even electronic systems used in aircraft and spacecraft.

- Military: The hydraulic bench top press can be used in a wide range of military applications, where dependability is required under extreme conditions. Some of these applications include the manufacturing of communication equipment, weapons, armor technologies, and surveillance gear.

What Are Key Considerations Before Purchasing a Hydraulic Bench Top Press?

Before deciding on which hydraulic press to purchase, it’s important to consider the factors that will impact performance, efficiency, and suitability for your application. The press needs to fit your workspace, and fit your production needs. Here are some key factors to keep in mind before you make your decision on a hydraulic bench top press:

- Tonnage

- Size

- Controls

Tonnage

Tonnage refers to the maximum force the press can exert to deform, shape, or cut materials.

Depending on the model, the maximum tonnage a hydraulic bench top press can handle ranges from 1 to 20 tons. Lower-tonnage machines can achieve smaller, more delicate operations, while higher-tonnage machines can achieve higher-capacity applications. Here are some examples of typical operations for machines with different maximum tonnage ranges:

|

Tonnage |

Application |

|

1 to 10 |

Small precision tasks and light-duty applications, like pressing bearings or working with electronics |

|

10 to 20 |

Moderate stamping and forming, where versatility is needed |

Incorrect tonnage, whether too much or too little, can lead to significant ramifications. If your press can’t handle the proper tonnage for your application, parts could be poorly formed. This could reduce efficiency and potentially lead to wasted material and added costs. Using a press with too high a tonnage can limit your ability to operate at lower force levels for jobs that require less pressure.

For example, let’s say you have a machine with a maximum capacity of 12 tons, with an operating range between 3 and 12 tons. This means that if you needed 1 ton of force, you wouldn’t have the ability on a 12-ton press.

Size

With a bench press, the right size depends on what you’re making and how you’ll be using the machine. A manufacturer can help you determine the correct bed size for your project once you consider these key factors:

- Bed Size/Work Area: Make sure the bed size can accommodate the largest workpiece and any tooling you'll be using. If you need more flexibility, consider a larger bed for your hydraulic bench top press.

- Daylight: This refers to the maximum open height between the platen and bed of the press. This must be enough space for the part or tooling stack-up, as well as to allow for easy placement and removal of parts.

- Stroke length: The distance the ram must travel to complete the function effectively.

- Press Speed: The cycle speed required to meet production volume needs.

Controls

When it comes to a hydraulic bench top press, control refers to the operator’s ability to manage and adjust what the press does. This involves managing its force, speed, direction, and stroke, which allows for efficient and precise operation. Here’s a bit more detail on each of these adjustable controls:

- Force control: The amount of compressive force applied to the material

- Speed control: The rate at which the press moves

- Directional control: The direction of the movement of the press - whether it extends (down) or retracts (up)

- Stroke and depth control: Setting how far the press can go during a cycle, reinforcing consistency

Are You Ready to Learn More About the Hydraulic Bench Top Press?

You now know the key features of hydraulic bench top presses and the advantages that make them stand out. They serve many purposes and industries. These machines offer great control, precision, and power in a compact form, making them great for a wide variety of applications and workspaces.

No matter the task, hydraulic bench top presses offer the versatility and reliability needed in manufacturing, whether in an industrial setting or specialized workshop.

If you want to learn more specifics, check out our offerings of the hydraulic bench top press or contact us to set up an engineering consultation.

.png)

.png)